PRODUCTS APPLICATIONS

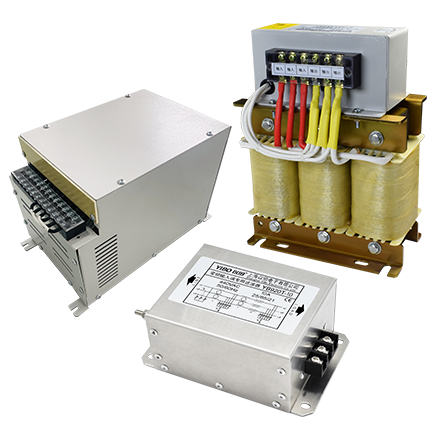

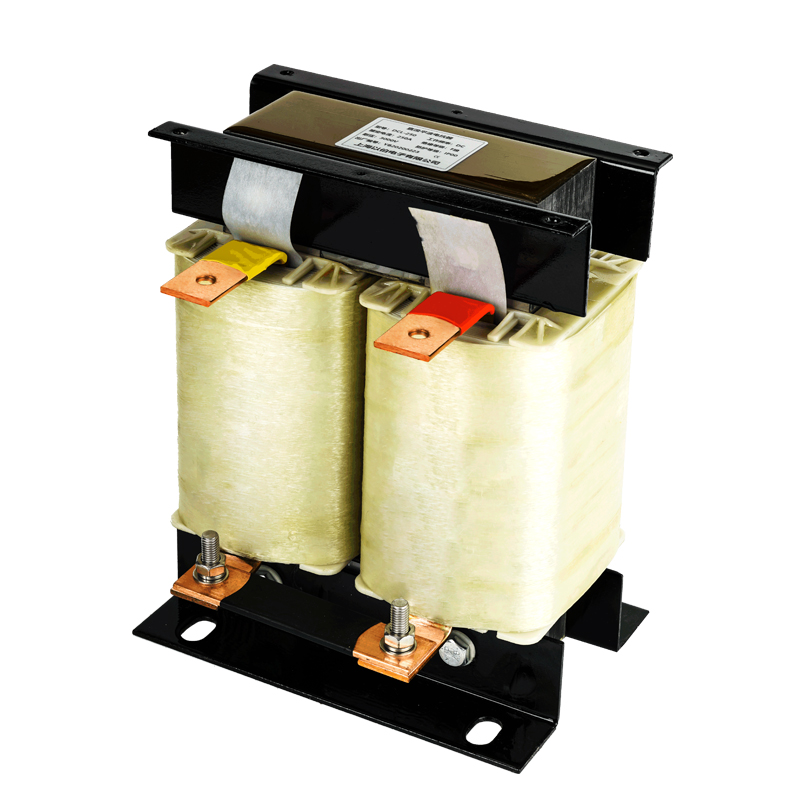

DC levelling reactor is used on the DC side of rectifier to suppress the ripple pulsation component after rectification, improve the output DC waveform and ensure the normal operation of DC equipment. If the rectifier output DC ripple is too high, then it is necessary to use DC flat wave reactor to achieve trouble-free phase change and reduce motor losses, the iron core is made of high-quality silicon steel sheet, the core column is divided into uniform small pieces by multiple air gaps, the air gaps are made of high-temperature, high-strength bonding adhesive to bond each small section of the core column with the upper and lower iron tightly, and the iron core end face is made of high-quality antirust paint spraying process to solve the problem of rusting of the iron core surface of the reactor, and greatly improve the DC waveform during the operation. Rust problem is solved, which greatly reduces noise and vibration in operation, and the reactors are painted by vacuum dipping process and cured by high temperature baking. Coils have good insulation properties, high mechanical strength, moisture-proof performance coil F, H level insulation system, greatly improving the reliability of long-term operation, low temperature rise, low loss, low cost, high utilisation rate, small size, light weight, small space, easy to install.