PRODUCTS APPLICATIONS

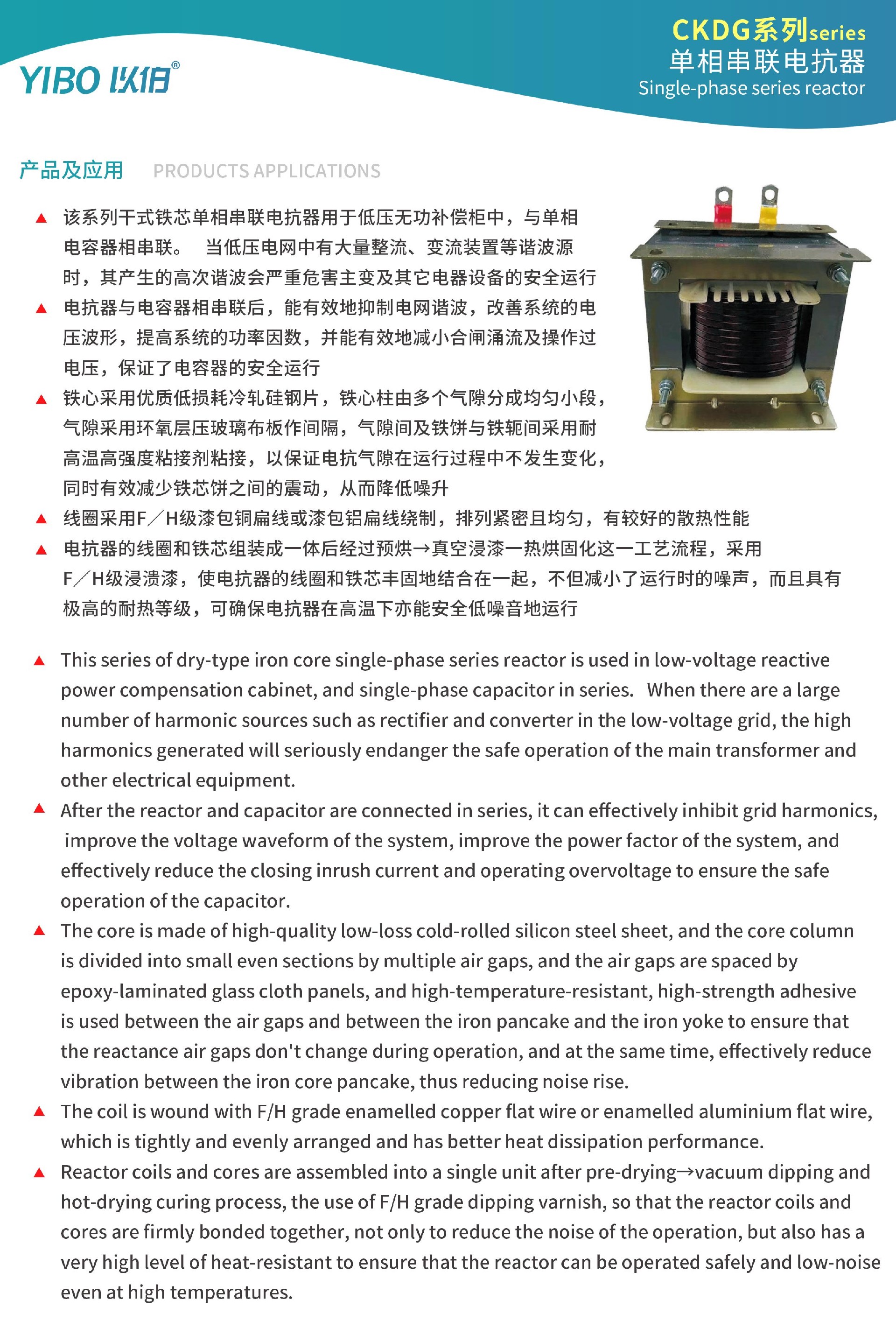

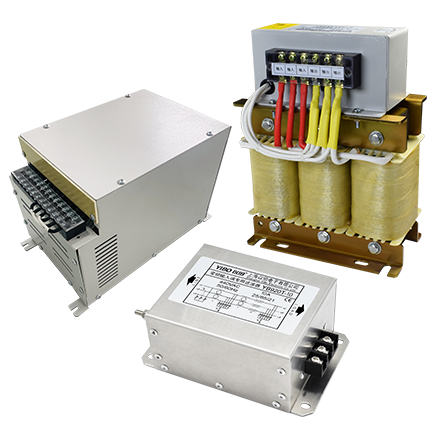

This series of dry-type iron core single-phase series reactor is used in low-voltage reactive power compensation cabinet, and single-phase capacitor in series. When there are a large number of harmonic sources such as rectifier and converter in the low-voltage grid, the high harmonics generated will seriously endanger the safe operation of the main transformer and other electrical equipment. After series connection of reactor and capacitor, it can effectively inhibit grid harmonics, improve the voltage waveform of the system, improve the power factor of the system, and effectively reduce the closing inrush current and operation over-voltage, which ensures the safe operation of the capacitor. The core adopts high-quality low-loss cold-rolled silicon steel sheet, the core column is divided into uniform small sections by multiple air gaps air gaps using epoxy-laminated glass cloth plate for spacing, between the air gaps and between the discus and yoke using high-temperature-resistant, high-strength adhesive bonding to ensure that the reactance air gaps do not change in the operation process, and at the same time, effectively reduce the vibration of the iron core between the discus and thus reduce the noise level. The coil is wound with F/H grade enamelled copper flat wire or enamelled aluminium flat wire, which is closely and evenly arranged and has better heat dissipation performance. After assembling the coil and core into one piece, the reactor undergoes the process of pre-drying→vacuum dipping paint and hot-drying curing, and adopts F/H grade dipping paint, which makes the coil and core of the reactor firmly combined together, which not only reduces the noise in operation, but also has a very high heat-resistant grade, which ensures that the reactor can operate safely and low-noise even under high temperature.