PRODUCTS APPLICATIONS

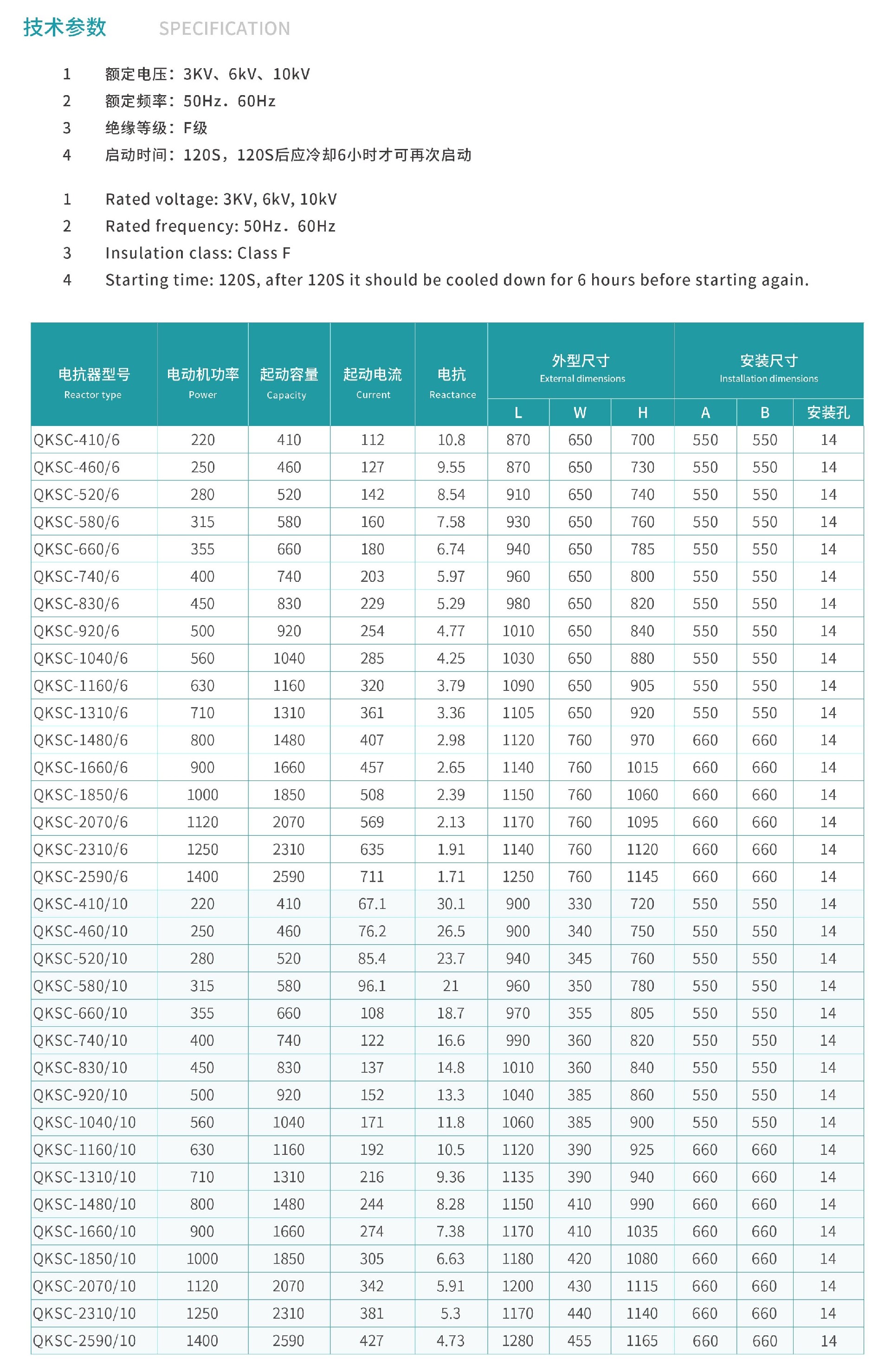

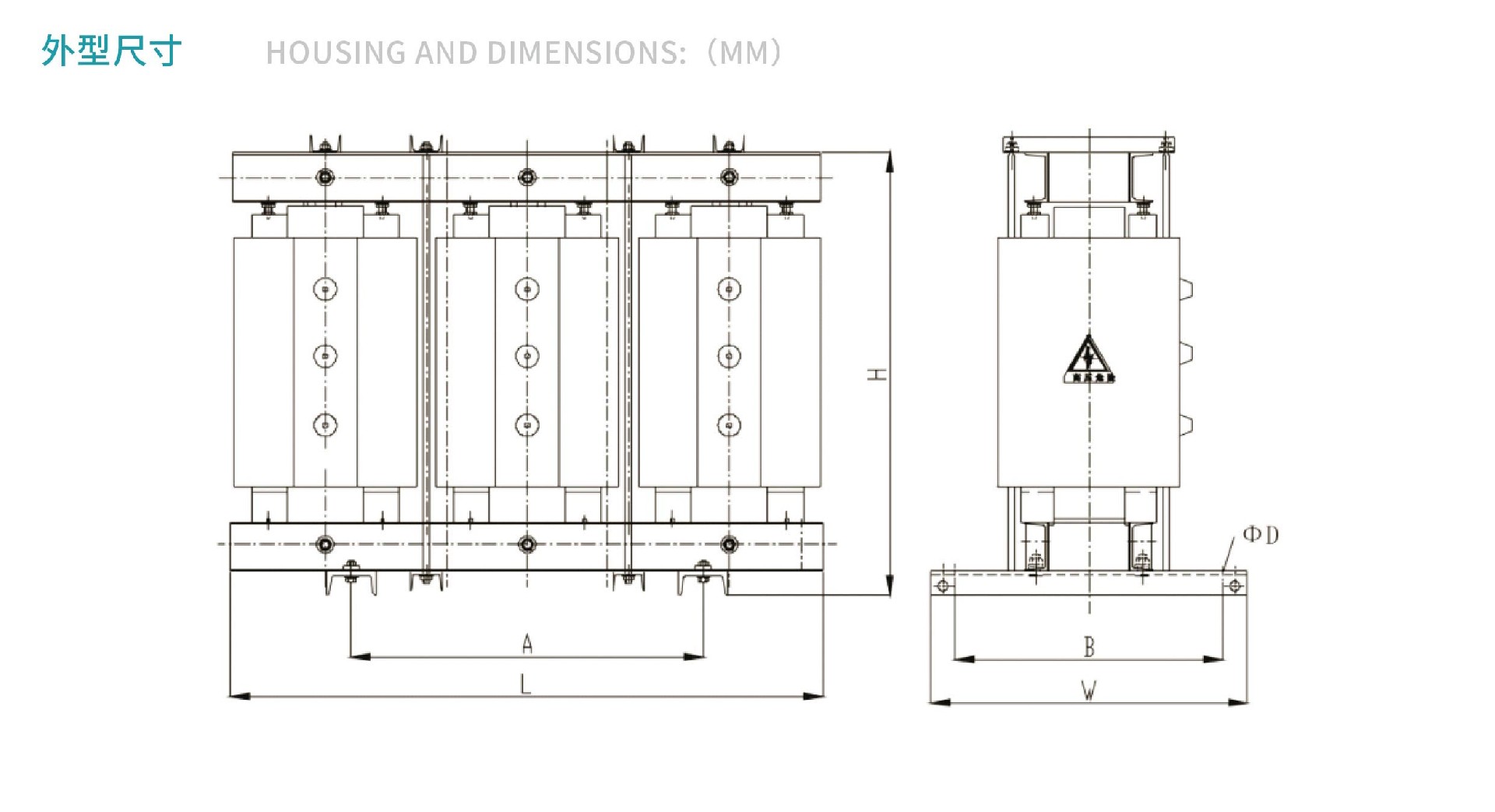

PRODUCTS APPLICATIONS When AC asynchronous motor starts under rated voltage, the initial starting current is very large, often exceeding the rated current many times (generally 5~7 times) In order to reduce the starting current, not to make an impact on the power grid, it is common to start AC asynchronous motor by lowering the voltage, which is designed in accordance with the start-up characteristics of high-voltage asynchronous motor. This product is designed according to the starting characteristics of high-voltage asynchronous motor, matched with motor power 220~1400kW. the core column adopts epoxy resin vacuum casting, so that the air gap between the iron cake is closed by epoxy resin and a resin layer is formed on the surface of the core column, which effectively reduces the mould movement between the iron core cake and thus reduces the noise, and at the same time, enhances the insulating strength between the iron core and the coils. The coils are epoxy resin vacuum cast coils. The coil is reinforced with epoxy glass mesh cloth inside and outside, and the epoxy casting system of class F is used for casting under vacuum. The coil not only has good insulating properties, but also has high mechanical strength and can withstand high current impact and cold and hot impact without cracking. The core end face is made of high quality silicon steel sheet end face adhesive, which makes the core column and the yoke firmly combined together and greatly reduces the noise during operation Advanced vibration and noise reduction structure system, including: strong pressure violet of the upper and lower clamping pieces, set up an elastic rubber pad between the clamping piece and the coil, and cast an elastic rubber pad between the clamping piece and the base.